MODULAR HANDGUNS: A FALSE PROMISE

Modular pistols are often marketed as highly customizable, but in reality, their design prioritizes cost-effective manufacturing and ease of maintenance over true modularity. The interchangeable components are typically standardized parts that allow manufacturers to streamline production and reduce expenses rather than offering users significant flexibility in configuration. As a result, while some changeability exists, the core platforms remain largely fixed, with modular claims serving more as a marketing angle than reflecting meaningful adaptability in function or form.

NOTHING NEW

If you believed that the Sig P320 was the first pistol to use a chassis system where the chassis was serialized, I am sorry you fell for it. You have been sold a terrible lie and you have been deceived terribly. Often Manufacturers will try to use false advertising or obfuscation of facts to try and garner consumer interest. In this case, most of you fell for it.

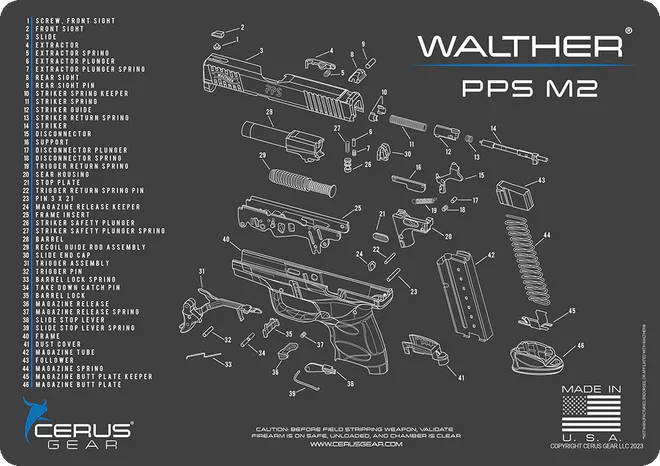

I have seen the chassis concept being used for quite some time in pistols like the Walther PPS.

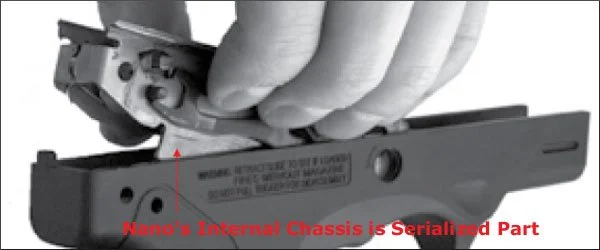

My Beretta Nano also used a chassis system that made the pistol easy to service, and Beretta even sold different color frames for it. And this was back in 2011

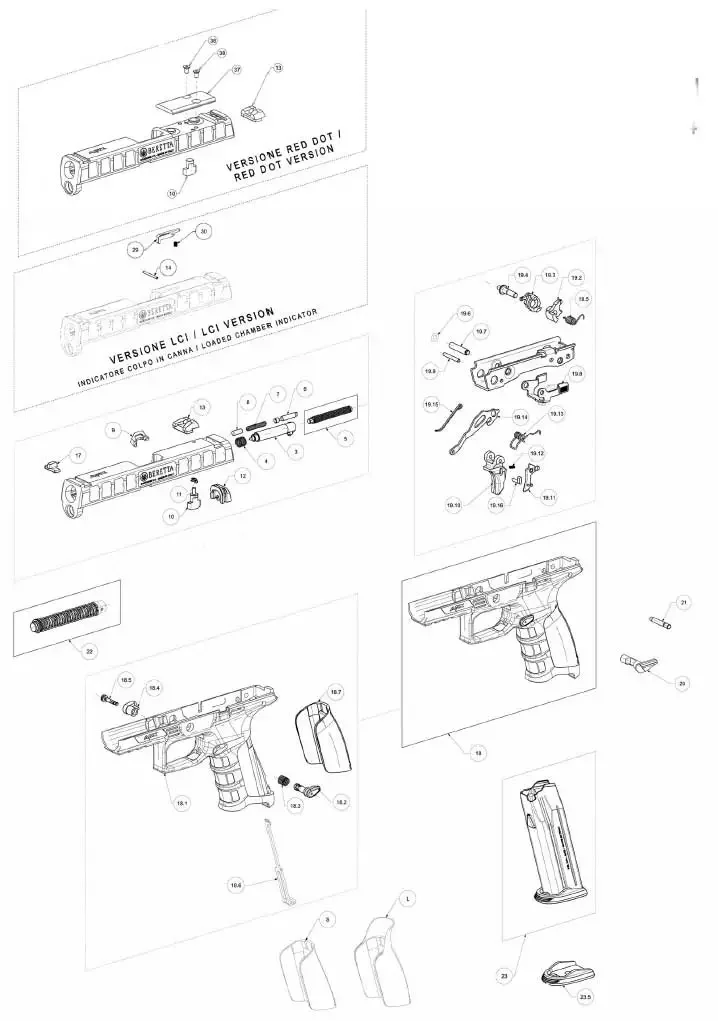

This same system is in the current APX compact carry and there is a larger version used in the full size APX series.

The Kel-Tec P11 and PF9, along with the SCCY pistols, were chassis systems too. All of the listed pistols had their serial numbers on the chassis instead of the polymer frame.

The Steyr M9 pistols used a chassis system that was easily removed long before the Sig P320. This was to save costs and assist with mass-production and ease of servicing.

CHASSIS SYSTEM PURPOSE

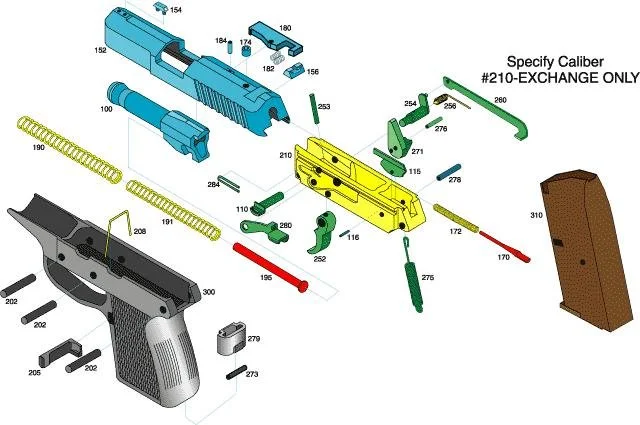

Look at the chassis system when removed from a firearm.

SAR9 Chassis

The grip is nothing more than molded polymer and a spring-loaded mechanism for the magazine release.

The chassis systems are merely small parts, pins, and springs that are inserted and pinned into a stamped and bent steel chassis.

The total amount of metal put into the frame of the modular firearm is relatively the same as the conventional pistol, but it is so much easier to access each individual component. There is no need to have a complex molding system to insert steel reinforcements into the frame. Also, it is now much easier to service and assemble the pistols in a factory setting. This merely allows the pistol to be made cheaper, and still be capable of achieving high round counts and have parts serviced with relative ease.

FEATURES/MODULARITY?

On firearms like the SAR9, H&K CC9, Beretta APX, Springfield Echelon, and the Steyr M9, they offer one frame size and maybe a few backstrap options in colors. Sig P320’s offers different frame sizes and colors, but zero slide options/kits. All of these pistols seem to be advertised or reviewed as being modular in the sense that the chassis can be moved from one gun to another. I get that this is a legit function of the chassis system, but it is not there to help the end-user. There are definitely benefits in the chassis system, but it has NOTHING to do with modularity or platform flexibility. That is like saying the Glock is modular simply because the mass-produced internals are able to be swapped from one gun to another.

EASIER PRODUCTION

The maker of these “modular” chassis-based pistols can now produce a million chassis assemblies and have 3 different types of guns produced (200,000 sub-compacts, 300,000 compacts, 500,000 full size pistols). In the past, companies had to play all these dimensional games and redesign the entire system to make a new pistol size, and struggle to have interchangeability between pins and springs. On assembly at the factory, workers needed to be trained to insert pins just right without marking up the frame, and ensure that parts were fitted correctly. This could take weeks or months for an assembler to be the hang of how to assemble a pistol with properly fitted parts.

With the chassis concept, only the slide and the recoil system need to be significantly engineered. It takes less training and experience to get an assembler to be able to assemble the pistols and get them out the door. There is much less fitting that must be done during the assembly process, making production more efficient in terms of time and money. Also, individuals can be easily trained to service these pistols at a factory and armorer level. There are still parts that need to be made to exacting or tight tolerances such as the Chassis band that features the rails and the slots for all the pins and springs. But, in general these components are much easier to make, resulting in the entire system becoming more cost-effective overall.

MHS PROGRAM PISTOLS

The Sig P320 is sold to the military for $230 per unit. I am pretty sure this was the base cost of the pistol, and Sig was hoping that just the notoriety of having a military contract would result in large civilian sales where the pistols go for a premium, often three times the cost of what the military paid per unit. Sig had really been taking advantage of this and advertising all their products as “military-grade”, and charging pretty pennies for their weapons.

If we look at other pistols from the MHS program, you will see that the cost they were offering the military per unit was about half of what you will pay commercially on the civilian market. Recently, Poland purchased thousands of the Beretta APX pistols for roughly $310/EUR263 per pistol. Commercially, this pistol costs $400 in most stores. Since the MHS, the APX has been slightly changed to accommodate the civilian market with things like changes to the frame and slide, and a change from the Bruniton (Phosphate treatment) finish, to a Cerakote-like ‘Aqua-Tech’ finish, which is a nano-ceramic finish designed to work better against corrosion.

The LAPD recently adopted the FN 509MRD as their official duty pistol for the 10,000 officers in the department. Commercially these pistols go for about $800, and I would bet the LAPD is only paying half of that per pistol. This is a big score for FN, since the testing that led to the adoption was well-celebrated.

If we compare the price of the FN, which does not operate off of a chassis system, and the Beretta and Sig, there is a notable difference in price. If you look at the schematic of each pistol, you may note that they are going to have a slightly different number of parts and complexity. However, does this translate to better or worse durability or reliability?

WHO BENEFITS?

The only ones that truly benefit from the chassis system is the manufacturer. Manufacturers can produce these pistols for a fraction of the cost of traditional polymer-framed pistols, but still charge the commercial market the same price as conventional pistols. This reduction in production cost will make them very attractive to law enforcement and military clients all over the world since they will be the only ones paying just above the cost to make each pistol.

Look at the designs and look at whether it is actually a net benefit for the end user, or just a way to promote a new little design like a direct mount cut on the slide or a different and cheaper manufacturing process. For instance, the Echelon is getting a lot of praise lately, and it very well may be an indicator of the way pistols are going to be made from here on out.

DURABILITY

With the chassis design, some people may be concerned about the durability of the system when all the components are wrapped up in a chassis and a frame. In theory, the chassis system should not provide any significant advantage to function and reliability. Reliability and durability are based on the stresses put on the individual components and the working life of the springs.

More companies are going to flat wire recoil springs instead of the classic coil springs. These flat wire springs last longer and hold their tension better, even though they typically are more expensive to produce. Parts that do not need to be made of metal, such as guide rods, are now made of polymer, allowing the parts to be molded in batches by the thousands. Making parts out of polymer over metal help make the gun lighter and the parts less expensive to produce and maintain.

WRAPUP

Polymer framed striker-fired pistols are the most common on the market today. Now the technology for these pistols is trending toward chassis designs. This is indeed the way to the future for pistol manufacturing. Whether we like it or not, this is the new standard for pistol designs. It is also starting to spill over into the rifle market with “drop-in” parts. The future is looking very bright for firearm development.